We are almost done with the manufacturing part of our project. We will then add one more update on the Analysis of Sound once the entire product is constructed.

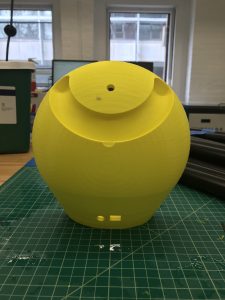

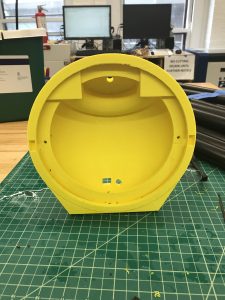

We printed the first model of our Casing and Handle (each in yellow below). When testing the fit, they were perfectly compatible when is rest position, but as we tried lifting the handle, the shape of the cut out in the body of the casing interfered. This was our first challenge. We then redesigned the fit of the two pieces to allow for a smoother movement when using the handle.

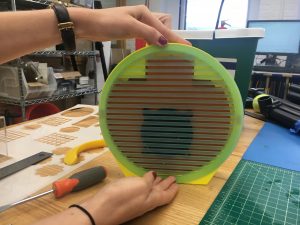

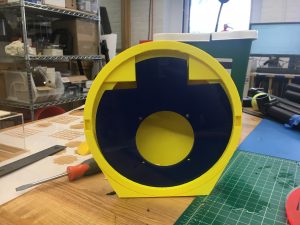

We also laser cut afew pieces to begin testing forsize. We cut a front face plate with slotted lines (blue below) to cover the entire electrical circuit. We also cut an internal panel to hold the driver. The last piece was small rectangle to attach the face plate to the casing body with a force fit. We had some problems here as well. The hole in in the internal panel for the driver was too largeand would not align correctly, so we redesigned it until it fit. The force fit pieces were too small and would not hold the face plate in place and so we enlarged them as well until they were the correct size. All of these small design decisions would add up to allowing us to build a fully functioning speaker.

We also began testing colors in order to see what we liked on the 3D printed materials. If you have any opinions on the choices below, let us know!

Lastly, with all of our minor adjustments, we had to adjust the layout of our circuit and Jim has been incredible with helping us fit the circuitry into any design we have created! By tomorrow we should have it all put together and will update on our success!