General Conclusion:

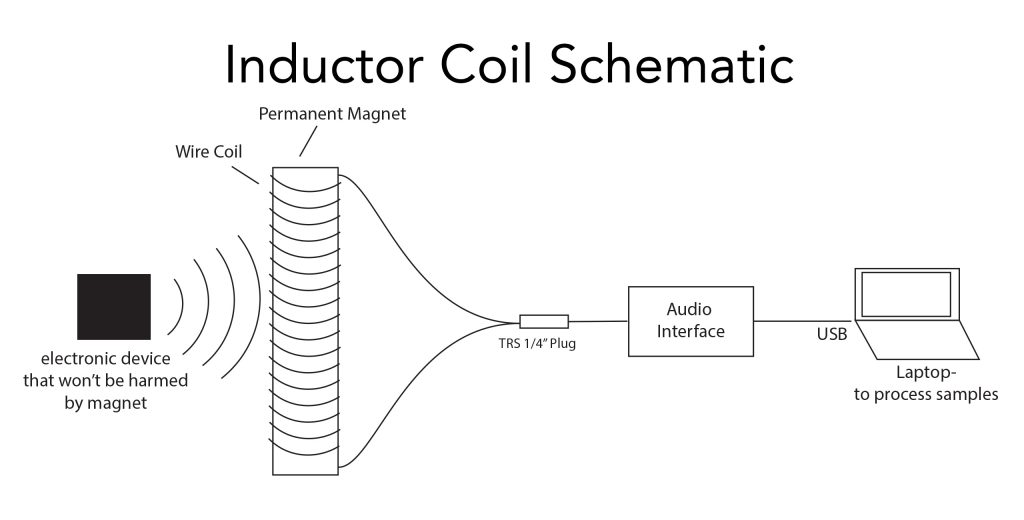

Over the course of this project, we have explored primarily three engineering principles: building/shop-work, induction, and audio engineering. We ultimately created a functioning, if not noisy, inductor coil pickup, which we used to collect various electrical signals which are not typically interpreted as audio. We had no way of predicting what our samples would sound like, as there appears to have been minimal prior investigation into how these signals could manifest as audio, but we were pleasantly surprised and perplexed by the variety of sounds we “found” in everyday items.

Quality of Pickup:

The only sample of ours for which there was a pre-existing precedent was the one of the guitar. Below are four audio samples for comparison:

1) Electric Guitar’s (Mexican Fender Stratocaster) professional-grade inductor coil pickups:

2) Acoustic Guitar’s (Seagull Acoustic-Electric) professional-grade piezoelectric pickup:

3) Our pickup used with the Seagull Acoustic-Electric (steel string guitar), unedited (noisy):

4) Same as example immediately (3) above but noise reduced with EQ adjustments:

Production Takeaways:

With the sounds recorded, we took to our DAWs. Emily used Protools, and Sean used Ableton to organize and process the samples. Emily mixed the sounds into a continuous, flowing piece that introduces each sample, one after the other. The purpose of this piece is to show both how these frequencies, which are alien to our ears, actually sound, while simultaneously laying a foundation which allows for comparison with the altered samples in the second project. Sean took these samples, and played around with them. Numerous effects (such as filters, chorus, delay, redux, etc.), VSTs, and several other audio units were used in the manipulation of these samples. The end result is a short piece which combines elements of various audio effects we’ve learned about throughout the course to create something entirely new.

What We Each Did:

We worked together very closely on the entirety of this project; we did all planning, building, and testing together. Closer to the end of the project, however, we split up the production work a little bit; Sean took the lead on the Ableton Live production of our final composition while Emily mixed the montage of raw samples in ProTools and constructed the Powerpoint presentation.

Minimally Edited, Mostly Raw Sample Montage:

In order of appearance: Digital Alarm Clock, Vending Machine Credit Card Reader, Light Switch on/off, WiFi Router, Samsung TV Remote, Xfinity TV Remote, Microwave

Final Composition: