Design Approach:

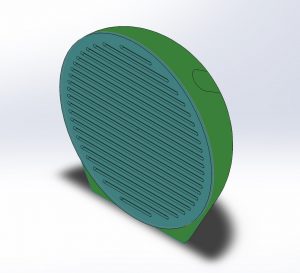

Below is an image of our CAD model for our speaker. It is 8.5in x 8.5in and 3.2 inches deep. The thought process behind these dimensions was that we wanted it to be portable, while not miniature. We are bringing the boom box back. This also allows enough depth for most drivers that we will decide between to fit within the housing.

The materials we have chosen for our housing are mainly acrylic (for the front piece) and plastic to be thermoformed into the back casing. The reason we chose to thermoform is because it allows us to create the entire back half from a single piece of plastic using a simple mold to create our exact intended shape, and it is a lot faster than 3D printing the piece. The acrylic front allows us to shape it easily with laser cutting, and cut slots throughout the front. While the decisions we have made for these materials are mainly focused on manufacturing considerations, we are not worried about their affect on the sound. We plan to fill the inside of the casing with a foam material to reduce the sound waves reflected off of the casing itself.

Below is also an image of our intended circuit within the housing unit. This may change as we determine the driver we plan to use, but we will update this page as our design changes. We also have a list of the components and connections shown.

(Source: https://makezine.com/projects/make-34/monobox-powered-speaker-2/)

Can you describe that circuit in more detail please? Maybe a schematic with component values and what it’s supposed to do? Check in with Jim about speaker circuits and encasings.

Hi Salma! We have actually changed the design for the circuit completely! The new circuit design will be included in the update we post tonight. Feel free to let us know if you have any more questions once its posted!

This looks cool so far! Do you think that the thin thermoforming plastic will be too reverberant (harder to dampen, or will the foam inside take care of it)?

Hi Cole,

Thanks! We actually switched to 3D printed material for more structural support, but I think the thinness of the plastic might cause it absorb more of the energy from the sound waves more than reflecting the waves.

Great question Cole! Actually, we have come to the same conclusion that you have hypothesized here and are changing to using a 3D printed back casing for the speaker. More details on this in our next deliverable!

This looks super cool. When you say you’re bringing the boombox back, do you mean it just in terms of the speaker’s appearance? Or is there something about the sound quality of boomboxes that you’re interested in?

Our intention is mainly in the appearance of the speaker and the design of its aesthetics. As product design- minded students, this idea of having a clear image of an intended model or feel for our product seemed helpful in producing a desired product.

Hi Joe, I’m seconding Sophia’s comment about trying to emulate the appearance and (hopefully) the functionality of a boombox (in its significance as almost an accessory). However, our speaker will also be pretty loud, like a boombox!

Given that you chose the encasing based on aesthetics, can you analyze the sound you get from this speaker and trace any interesting qualities or anomalies to the actual physical choices you made?

Never mind… I see that I already said that in your first post 🙂

We have definitely try to analyze the sound best we can. With our limited time we were not able to dedicate as much time as we had wanted to to the analysis, but we still came away with a strong sense of how well our speaker functions. Sadly, even when we find problems with the sound or anomalies and unexpected outcomes, we were not able to attribute them to any specific traits of the speaker, although we can, and have, speculated th causes.