Potential future scenario of Lithium, Electric Vehicles (EVs) and the rise of alternate energy like Hydrogen

Written by Zeng Han-Jun

The energy crisis sparked by Russia’s military aggression had many rethinking about the future of energy and justly as well, because both events, the Covid-19 pandemic and Russia’s military aggression have disrupted supply chain and caused energy prices to spike. This has affected many people’s standard of living in many ways, one of which is to physically suffer through the cold weather and it might get worse during winter. I strongly believe that those who spent most of their lives in the global south, might find it difficult to understand how bitter cold winters can be in some parts of the world and the importance of keeping warm when it freezes. It is a very painful lesson that stemmed partly from over-relying on a handful of traditional energy sources.

As such, it is logical that there is a growing demand for alternative energy sources in many areas, from powering factories, heating up homes and offices, to moving vehicles. In the earlier phase of the growing demand, the narrative was that using fossil fuel is bad for the environment because of the substantial release of carbon into our atmosphere. That awareness played an important role in promoting electric batteries as an alternate mean of powering vehicles.

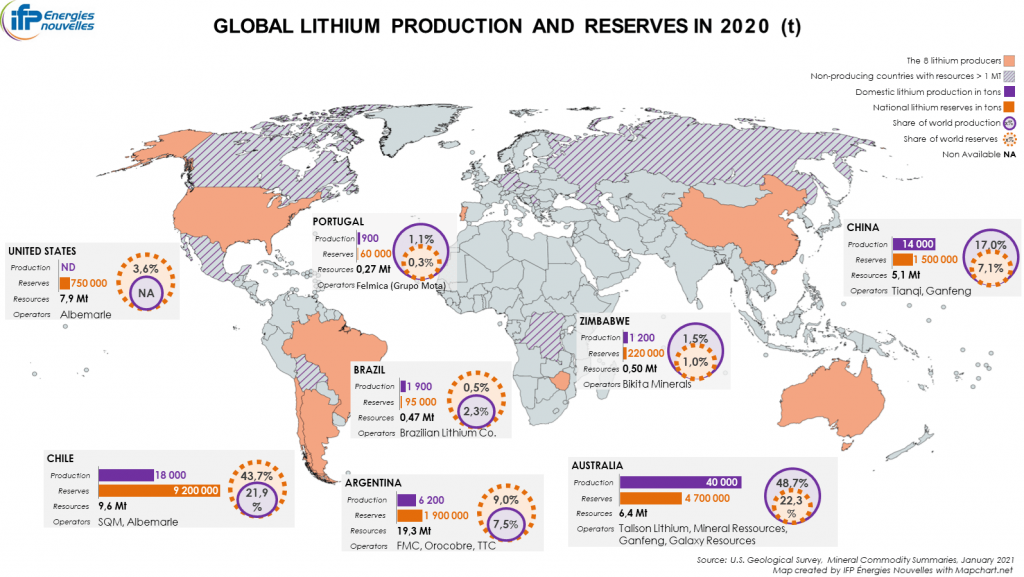

In my earlier think piece, I discussed about the current production level of lithium, which is an important component of the EVs’ electric battery, and how it pales when compared to the estimated demand for lithium by 2030. If you refer to the heat map below, you would be able to estimate that the total global lithium production stood at roughly around 82,200 tons. Several current estimates and studies showed that the total global demand for lithium in 2030, will go far beyond 82,200 tons. In exact figure, it is more than 1.9 million tons which is equivalent to 23 times more than the total global production figure in 2020.

Now, if you were to refer again to the heat map produced by the U.S. Geological Survey, you will gather that the total global store of lithium is roughly about 50 million tons. At the first glance, it may seem that we have enough lithium to go around and technically could continue with mining. If the global demand is to peak at 1.9 million tons in 2030, there is still enough lithium to extract for another good 26 years, but in reality, demand for lithium will most likely continue to grow after 2030.

This is why analysts have put out the figure that we could be in short supply of lithium by 2050. Some people that I have spoken to, believe that lithium recycling technology would be more stable and productive, thus enabling the circulation of mined lithium for industrial uses for many more years after 2050. And this is their justification for greater activity in lithium mining.

We would if we could but should we really do so?

I think that it is not feasible because of the following five reasons. First of all, the physical disturbances to the environment and communities that are living near to the mines. Second, carbon emission of the mining operations. Third, the future geopolitical tension that it creates and fourth, creating a single point of failure by focusing too much on electric batteries. Let me explain why.

1. Physical disturbances to the environment and nearby communities

Now, partly because of expanding interest in sustainability, people are starting to understand the impacts that some human activities, including mining, has on the environment. I see that the current narrative has evolved into questioning whether or not Electric Vehicles (EVs) are truly one of the silver bullets to saving our environment or merely just kicking the can down the street. First of all, I noted that many apply a broad understanding of what they know of mining i.e. the usual digging of earth, crushing boulders and deployment of many environmentally unfriendly technology, to lithium mining. Mining activities are generally all the same, but it is quite different with lithium mining at the moment.

Lithium is historically known to be produced from two sources: brines and hard rock mining. Lithium produced from brines is a cost-efficient process. These brines containing lithium are derived entirely from the leaching of volcanic rocks. The cost of lithium produced from hard rock mining is double than that of what is extracted from brines containing the metal. Mining starts by drilling a hole and pumping brine to the surface. Miners then leave it to evaporate for months, first creating a mix of manganese, potassium, borax, and salts which is filtered and placed into another evaporation pool.

It would take roughly between 12 and 18 months for that mix to be filtered enough in order to be able to extract the lithium carbonate. While it is relatively cheap and effective, the process needs a lot of water, estimated at 1.9 million liters per ton of lithium extracted.

For perspective, it was estimated that it would take around 63 kg of 99.5% pure lithium to make a 70 kWh EV battery pack. This means that the manufacturing would use up more than 119,000 liters of water, equivalent to satisfying a single full grown person’s drinking need for 32,162 days (~ 88 years).

That’s just one way to see it. Here is another way. Estimates of water audits showed that it takes about 237 liters of water to produce about 1 kg of cabbage, so instead of producing one battery pack, with the same amount of water, you could technically produce about 502 kg of cabbage which I think, could be used to feed a small family for about a year or so? Instead of cabbages, you could also divert water to planting trees as well. So, the mining process diverts water away from what the environment and man need.

These are the opportunity cost to manufacturing a single EV battery pack. However, I could also reframe my thinking and adopt a green and longer-term perspective. I could adapt the single battery pack to other environmentally friendly uses that might potentially produce more water, food, greenery or other social benefits than what the manufacturing originally consumes. That being the case, I might essentially, at multiple levels, be producing an ESG- (Environmental, Social and Governance) friendly product.

2. Carbon emission of the Lithium mining operations

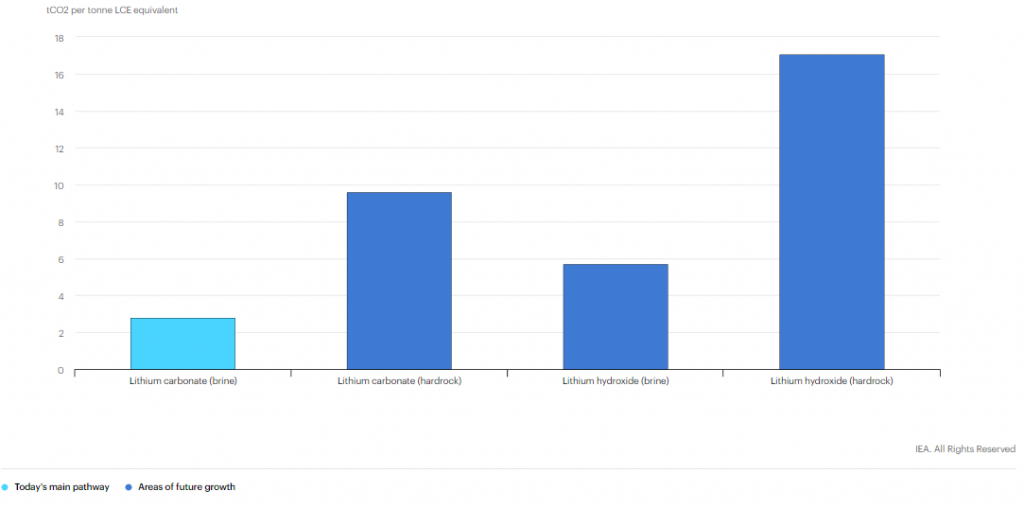

The below graph, produced by the International Energy Agency in 2021, is a very interesting chart. It shows that the current Lithium mining pathway produces roughly about 2.8 tCO2 per tonne LCE equivalent, much lower than most other types of mining operations.

At this level of activity, the production houses are churning out roughly about 82,200 tons of lithium (2020 figures). We would have to activate or maybe even develop other ways of extracting lithium if we are going to meet the growing demand. Meeting growing demand for lithium could lead to higher carbon emission. Based on this graph, by activating all known means at the moment, we would increase the carbon emission of lithium mining to 35.2 tCO2 per tonne LCE equivalent, from 2.8 tCO2 per tonne LCE equivalent (~ 1,257% increase).

Most people would think that since other types of activities are faring much worse, so why the focus on lithium mining? The thing is, every bit counts, and the ESG and sustainability focus is slowly and surely extending to all domains, not just lithium mining. Provided that no major events occur and shake the fundaments of the current world structure, ESG and sustainability certifications and regulations most definitely will cover all industries in the future, hopefully moderating carbon emission and ease the global temperature rise to a more human-acceptable level.

3. Potential geopolitical tension

It is no secret knowledge and almost everyone knows about it, dominance over or at least keeping close to raw materials, is one of the key chess moves that could advance one’s strategic position. If EV ecosystem, comprising all types of mobility devices or modes, is the chess game, then lithium is one of the key components to triumph. Looking at the above heat map produced by the U.S. Geological Survey, one could get a rough give-or-take intuitive sense of who is dominating the chess game.

What this means is that, if there is anyone who is a little bit keen on any of the EV-related businesses, they should start to join the winning side or at least slowly start divesting away from the disadvantaged side.

4. Creating a single point of failure by focusing too much on electric batteries

If there are any learning lessons to distill from the Covid-19 pandemic and Russia’s military aggression, I would say that it is the identification and continual mitigations of any single points of failures to important functions. Electric batteries are merely a store of energy, and this energy could directly or indirectly be derived from different sources such as fossil fuel, alternative energy or renewable energy. With the current technology, it is entirely possible to recreate a vehicle that is powered entirely by alternative or renewable energy, without the use of electric batteries.

When energy sources were threatened, scientists and engineers quickly leaped forward to develop new ways to powering vehicles. Similarly, if anyone were to push too hard the narrative of EVs while at the same time stifling competition, the tables could flip, thereby forcing competition to try to develop alternate propulsion methods which sidesteps entirely the use of electric batteries. In fact, the technology is already there and energy sources like hydrogen, ammonia, ethanol (from sugar cane), hydrogen fuel cell, solar, road-power, to name a few, are being implemented, adapted and integrated into existing vehicle technology. Even fuel stations are currently being adapted to provide different types of energy sources to vehicles. However, when it comes to safety, I place higher favorable weightage on electric batteries than hydrogen, and I will explain why later.

Hydrogen is a promising energy source, and another potential energy source is ammonia. One of the key areas to improve on, is to refine the waste collection and management system, then integrating that understanding into the process of producing hydrogen. This area holds a lot of potential to solving important environmental issues. As such, it is critical to adopt a holistic approach to tackling this challenge and I believe that it could only be achieved by viewing through the lenses of multiple urban system sciences without forsaking the operational details.

All details must be considered from an urban system science point of view. For example, positioning of the waste management plants, auxiliary waste management centers and hydrogen power plants, must be precisely planned, according to the future development plans, traffic patterns, national defense considerations, weather patterns and other natural phenomenon. More does not mean better, neither is less bad, but an optimal number of placements should enable complement strengthening of each other’s capabilities.

This is important in itself, and also extends its influence on the transport patterns of the waste management vehicles and the hydrogen transport vehicles, affecting factors like traffic volume and national defense. Exploration of Artificial Intelligence in augmenting this area is a promising area, still at a nascent level but definitely achievable.

In terms of safety, I think that electric batteries are the better solution compared to hydrogen. Electric batteries burn but hydrogen can cause extremely life-threatening explosions that can take down entire buildings within the destruction perimeter. Protective engineering techniques such as the strategic use of reinforced concrete, steel sheets and others, become very important subjects. The greater the underground hydrogen pipeline network proliferates, the greater need to build in more safety factors. Such consideration becomes exceedingly critical to providing a safe space in highly built up and dense urban environment. There were several past explosions involving natural gas pipelines in New York and the results were skyrocketing.

A lot of advance work is needed to develop the certified framework for pyrolysis process, hydrogen production and safety inspection at different stages of the value chain. Apart from that, substantial amount of time must be planned for the local workforce to gain sufficient expertise in these areas before rolling out the initiatives.

Copyright © 2022 Zeng Han-Jun. All Rights Reserved.

Claude Gerstle

September 4, 2022 @ 4:52 pm

Thank you for leaving your comments on the MIT open site and for your very thoughtful blog. When discussing climate change I find that most people address the problem nationalistic lay instead of globally and do not take into consideration past emissions. We need to get people to understand that developing countries are going to have much higher emissions in the future will still staying very much below the US emissions per person. It’s really necessary to look at and emissions budgeting scheme as the one available on the Maca site. Within 10 years the US will be over budget. Even if we went to carbon capture from all our point sources we would still be emitting at least 10% of the carbon from those sources and be over budget. That means we would have to be doing direct air carbon capture on the level of tens of gigatons per year. The less expensive alternative is to have a huge Marshall plan giving developing nations the energy sources they need but which have only a fraction or no emissions.

I understand your reluctance towards hydrogen As a replacement fuel. Hydrogen pipelines are somewhat problematic but it turns out that converting the hydrogen to ammonia, where we have extensive pipelines already in place and years of experience enable transport of an energy dense liquid requiring minimal compression and with new catalysts under development should provide round-trip efficiencies that make this economically viable. Add to that the development of solid oxide and hopefully other fuel cells that can utilize ammonia directly and the hydrogen economy becomes even more attractive.